Every time you play a record, have you ever wondered exactly what the disc in your hands is made of? Sure, a big clue is in the name of a vinyl record, but it’s got to be more complex than just a flat plate of plastic, right? What is vinyl?

I wanted to know what the make-up of a vinyl record is, so I went about finding out what goes into them, and why.

The resin mix which is used to create a vinyl record is made up of a blend of the following materials:

- Polyvinyl Chloride, more commonly known as PVC.

- Polyvinyl Acetate (PVA).

- Colorants.

- Heat Stabilizers.

- Plasticizers.

- Lubricants.

- Fillers.

The above ingredients are combined during the production process to manufacture the discs we listen to on our turntables, and every ingredient listed above has a variable but important role to play.

As well as looking at what each ingredient is, we’ll also understand what each of them actually does and why it’s included in the mix.

What Is Vinyl? These Are The Main Ingredients Of a Vinyl Record

So, let’s break it down and take a look at each of the ingredients we listed above.

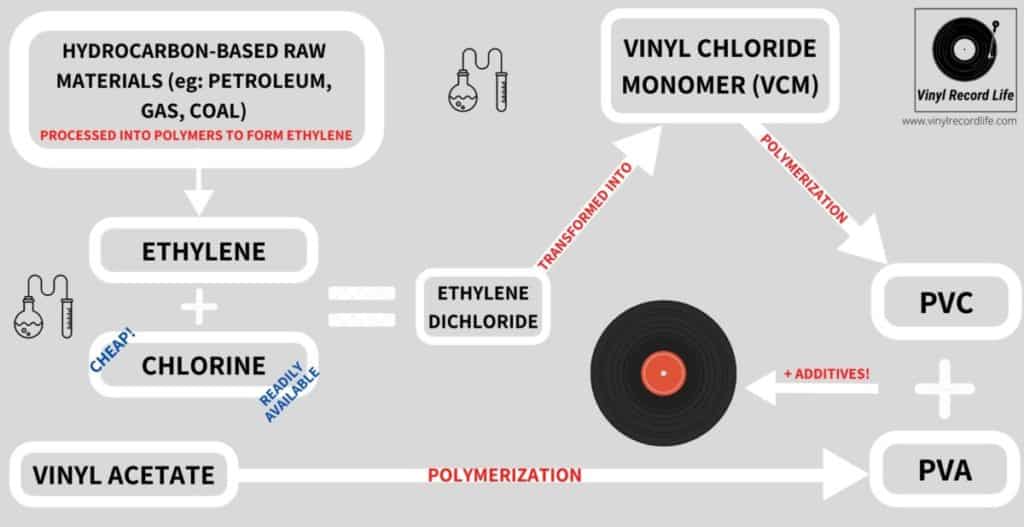

First up, the Polyvinyl Chloride and the Polyvinyl Acetate, or what we know in everyday terms as PVC and PVA (yes, the glue we used to end up gumming our fingers together with in school!).

To try and keep things as simple as possible, here’s a diagram with an overview of how PVC and PVA are created, and then combined, to form the base of the thermoplastic resin that will make the vinyl record.

Now, let’s look at those extra additives that go into the recipe for making a vinyl record.

Heat stabilizers are a key ingredient and serve an important function in this whole process. They are usually the metal salts of fatty acids, with the metals often being tin or lead, and usually more than one type of stabilizer is added to the mix.

Plasticizers are thrown in too, and these range from phthalate esters (stick with us here!) to epoxidized soybean oil. While PVC itself already has a good measure of the properties that plasticizers add (we’ll get to this a little later), it often receives a boost from this supplement.

Colorants usually come in the form of carbon black, which has a carbon content of 95%, and when filler is used in some resin mixes for records it will most commonly be recycled vinyl.

Finally, lubricants that go into the pot are typically hard waxes, either natural in the form of Montan or synthetic in the shape of Stearamide type waxes.

With the menu of these ingredients, manufacturers find their own balance and mix to form the resin for making vinyl records as they implement their own touch.

PVC blends are complex mixtures of PVC particles, fillers, lubricants, stabilizers and plasticizers. Manufacturers often must modify these recipes due to technological advances, cost pressures or regulatory requirements.

Matthias Jaehrling, ThermoFisher Scientific

Here’s a table that shows the approximate ratio of ingredients in a typical resin for a vinyl record, allowing for the variation from manufacturer to manufacturer, as resin mixes are unique to each factory:

| Property | Percentage of final record weight |

| PVC/PVA polymer | 96% |

| Heat stabilizers | <1.5% |

| Lubricants | <1% |

| Plasticizers | <1% |

| Colorants | <0.5% |

What Does Each Component of a Vinyl Record Do?

Now that we know exactly what goes into the vinyl record, we can discuss the specific purpose that each ingredient brings to the party.

PVC

PVC has been the base material for records for a very long time because it provides a few essential properties that make it so suitable. Its structure is anywhere between 10-20% crystalline, which makes it strong enough to support a groove being hollowed out of it and at the same time take a turntable’s stylus ploughing through without sustaining damage.

Other benefits of PVC is that it provides a quieter surface, is less brittle than previous materials which were used such as shellac, and it is able to store a substantial amount of music. Being cheap is also an important aspect in a business-driven music industry.

Plasticizers

The fact that PVC can be plasticized also makes it ideal, and the plasticizers play an important role in the formation of the record. They alter the PVC resin mix’s viscosity which improves its flexibility, and this makes it easier to match the microgrooves in the master disc during the pressing process.

This flexibility that the plasticizers bring also makes the finished product more resistant to breakage.

On its own, the PVC-PVA mix in the resin already has a decent degree of flexibility, but the additional flex brought by the plasticizers can increase the disc’s durability significantly.

Stabilizers

PVC has low thermal stability and being exposed to heat, pollution and UV leave the PVC open to degradation and breakdown. We all know how vulnerable our records are to heat and direct sunlight after all, and this is where the heat stabilizers come into play as they help to make the resin mix more robust.

In addition to this, the heat stabilizers also help to neutralize the hydrogen chloride gas which is generated at the temperatures reached during production. This gas can cause further breakdown, so the stabilizers help to combat this effect too.

Colorants

On to the colorants, and the use of carbon black doesn’t just give the record its distinctive black finish, although that is the most easily seen impact it has. The addition of carbon black as a colorant allows the surface of the record to be more easily observed, and thus the detection of defects such as scratches to be spotted.

Carbon black also brings a touch of extra durability to the resin mix, and serves one other important purpose in that it helps to distribute and dissipate electrical charges, thereby reducing the build-up of static charge on the record.

Lubricants

Finally, lubricants in the mix help ease the flow of the resin during the production and processing stages of manufacture. They also help to reduce friction on the record’s surface which has multiple benefits such as a reduction in heat and disc degradation, as well as a smoother contact between the record and the stylus.

Are Vinyl Records Bad For the Environment?

With all the ingredients we’ve discussed above, it’s a valid question to ask. In a word, yes, vinyl records are bad for the environment purely by virtue of what goes into them.

Vinyl records aren’t biodegradable. PVC comes from refined oil and can take up to 1,000 years to decompose. One saving grace for vinyl records is that they usually last generations and are passed down and recycled amongst record lovers, instead of ending up in landfills.

That may not offset the carbon footprint of the production processes and ingredients that go into making a vinyl record, but there is certainly a much longer lifespan of vinyl records as a consumer product, and they are re-used and passed from one user or generation to another.