Problems with a record player or turntable can often be traced back to a small number of root causes, and one area that is always worthy of a close check is the tonearm.

Perhaps you’ve already identified that the tonearm of your record player is the cause of whatever issues you’re encountering, or it may be the case that you’re experiencing some sound or playback problems but aren’t entirely sure where to look.

Whatever situation you find yourself in, the tonearm of your record player or turntable is such a vital component in a good set-up that troubleshooting it is usually a good place to start when looking for a fix.

What Is the Purpose of a Record Player’s Tonearm?

Before we get into the reasons behind tonearm issues and their fixes, it’s important to first understand exactly what a tonearm does.

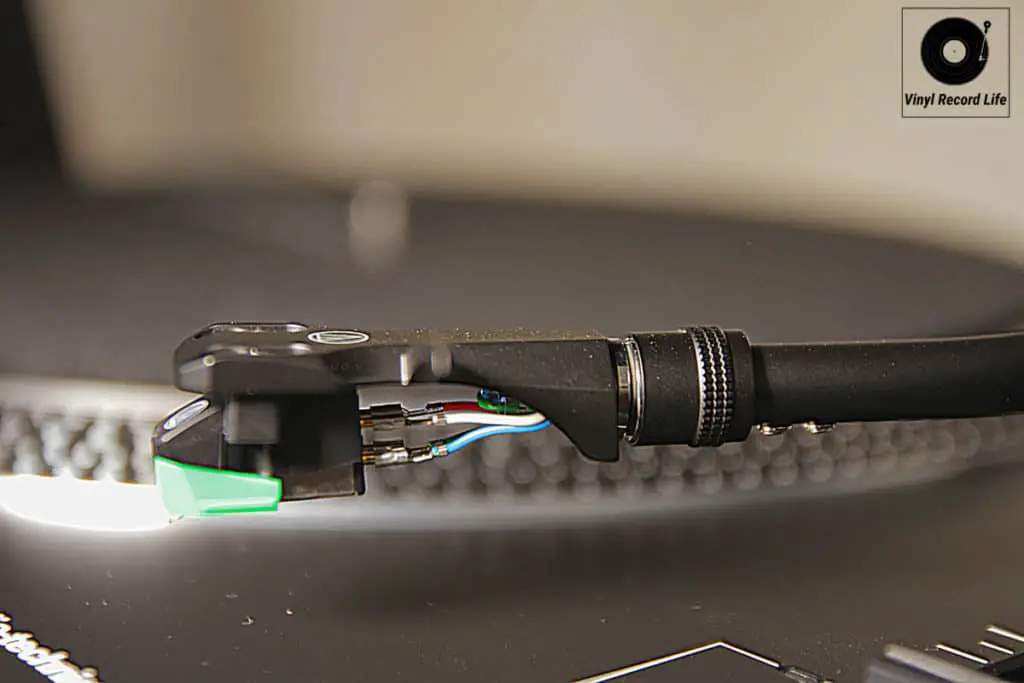

The tonearm supports the cartridge, which contains the stylus – or needle – and this is the critical link between getting the music signal off a record and through to your sound system.

A tonearm has multiple functions:

- It maintains a fixed height and angle, to ensure the cartridge remains in the correct position.

- It applies the correct weight and pressure, to ensure the stylus comes into contact with the record’s playing surface correctly.

- It applies the anti-skate force, to stop itself from swinging to the center of the platter.

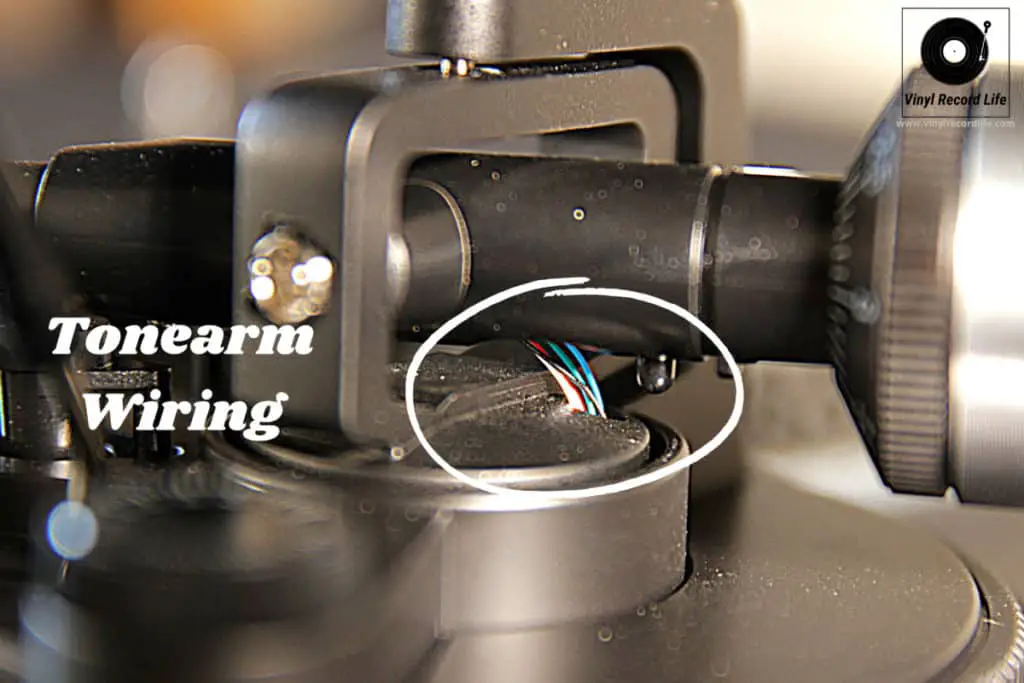

- It houses the wiring that carries the signal from the stylus, through the cartridge, all the way to the output.

The smallest issue with any of these aspects can influence sound quality, either independently or in combination with other factors.

There are also other mechanical issues with a tonearm that can affect the sound of your records, and it is for these reasons that proper tonearm set up is essential.

What Are the Most Common Record Player Arm Problems?

The most frequently encountered issues when it comes to a record player’s tonearm fall into two main categories: those which are visibly obvious mechanical problems, such as a tonearm that won’t lower properly, and those which are less apparent to the eye but which affect sound quality and result in an audible problem such as a skipping record.

In the below guide, I’ve split the common issues and their potential fixes into those two main categories. Here are the 10 common issues we’ll address in the guide that follows:

| Issues which present as visual mechanical problems with the tonearm |

| 1. The Tonearm Swings to One Side. |

| 2. Tonearm Won’t Lower All the Way. |

| 3. The Tonearm Drops Too Fast. |

| 4. The Tonearm Keeps Returning. |

| 5. A Bouncing Tonearm. |

| Issues which present as audible and which can, in many cases, be traced to the tonearm |

| 6. Hum or Noise When Playing Records. |

| 7. Weak or No Sound During Record Playback. |

| 8. Only Hearing Sound in One Channel When Playing Records. |

| 9. A Skipping Record. |

| 10. Interference When Moving the Tonearm. |

Before you read the guide and attempt any of the fixes, there are a couple of points it is important to be aware of prior to trying any of the suggestions.

The first is that you should always check and follow the manufacturer’s guidelines when trying to fix any tonearm issues. The second is that many issues can be solved with correct tonearm set up according to the manufacturer’s instructions.

As a starting point with any tonearm issue, you should always run through its set up as this will often help to clear out any problems.

If you don’t have instructions handy here are links to some of the main manufacturer’s own general tonearm set-up guidelines, which they’ve made available online:

| Manufacturer | Link to tonearm set up instructions |

| Fluance | Fluance website (opens as webpage) |

| Pro-Ject | Pro-Ject website (opens as webpage) |

| Rega | Rega website (opens as pdf doc instructions for RB330 tonearm model) |

| Audio-Technica | Audio-Technica website (opens as webpage) |

If you can’t find your specific brand/model’s instructions online, the general process is fairly standardized across most brands and models, and this Audio-Technica walkthrough provides a fairly comprehensive guide:

How to Fix Tonearm Issues: A Guide to Solving 10 Common Problems (with Pictures)

Let’s start with perhaps the most obvious problems you may encounter, and which you’ll most likely see in the shape of mechanical issues or odd behavior from your record player.

Issue 1: The Tonearm Swings to One Side

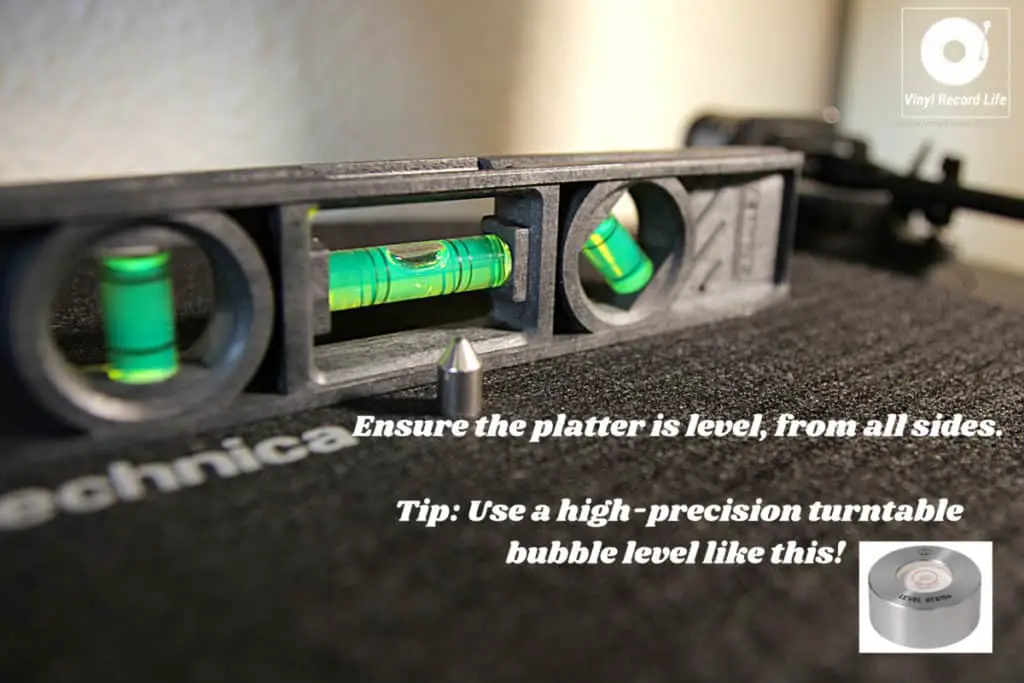

A common cause of a tonearm swinging when it isn’t supposed to is that the platter of the turntable or record player isn’t level. Many tonearms can be extremely sensitive, so being as precise as you possibly can with leveling the platter is very important.

Using a special turntable precision spirit level to ensure the platter is completely flush is highly recommended, and this is the one I use to get the job done.

If this doesn’t sort the issue out, another far less likely cause could be the tension of the wiring within the tonearm. This is much rarer, and if checking the balancing of the tonearm and the platter’s level haven’t solved things then this is a final check. This may be one you would prefer to get a professional to undertake.

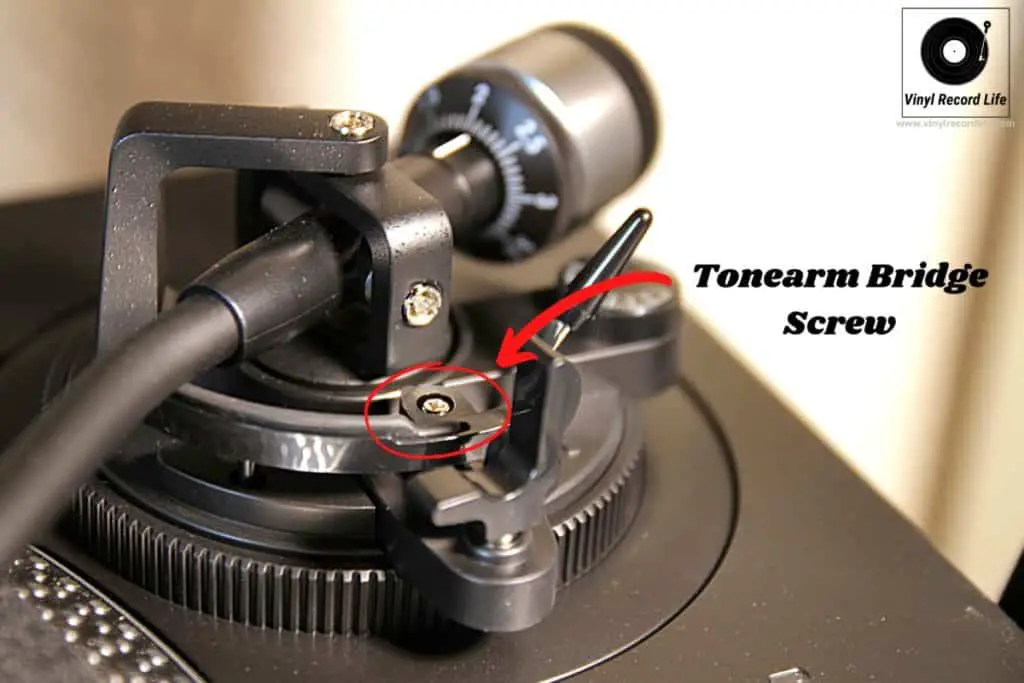

Issue 2: Tonearm Won’t Lower All the Way

You may be finding that the tonearm isn’t lowering far enough to bring the stylus into proper contact with the record on the platter. This is usually because the tonearm bridge is not lowering enough when the cueing lever is used. There is usually an adjustment screw you can tweak which will adjust the bridge’s height, and in turn solve this issue in most cases.

Issue 3: The Tonearm Drops Too Fast

If the tonearm is lowering too fast, this can also be a symptom of an issue with the bridge, so try the bridge adjustment screw as a first quick check.

If this doesn’t work, then the most probable cause is the damping capability of the cueing lever. A little perseverance with this fix will be required, but it’s worth it and is very satisfying when you do fix it!

A cueing lever mechanism is lubricated with fluid that helps to control the drop of the tonearm, and over time this fluid can see its effectiveness degrade as it dries out and loses its viscosity.

You’ll need to carefully apply some fresh cueing lever mechanism damping oil to the area. This isn’t a complicated process and is relatively straightforward, but the result will make the effort worthwhile.

This video does a good job of explaining the process, and also highlighting what happens if you apply too much fluid:

You’ll need to choose the right viscosity of dampening fluid to apply based on the weight of your tonearm – I’ve used this one before and it’s helped me maintain the tonearm on one of my turntables.

Issue 4: The Tonearm Keeps Returning

Some record players have a tonearm that automatically returns to its resting position after the record stops playing. These tend to be older “stacker” models (I have a 1972 Tonesta which has this feature), or the cheaper newer mass-produced models such as Crosley.

An issue with this style of record player sometimes arises whereby the arm returns to its resting position when it shouldn’t. A quick fix that often works is to manually rotate the platter with your hand for a few revolutions, until you hear a click sound. This will be the auto-return mechanism disengaging and/or resetting, and should solve the problem.

If this doesn’t fix it, check the model’s instruction manual to see if there is any mention of an auto-return adjustment screw.

Issue 5: A Bouncing Tonearm

If your tonearm is bouncing, it may be because of a few issues. If you’re manually lifting and lowering the tonearm, this may be causing a bit of a bounce when you release it.

If your turntable has a cueing lever, you should use it and execute a smooth lifting action every time. Tonearms are delicate and sensitive mechanisms and what may not feel like a particularly rough movement can result in damage.

Another cause of a bouncing or non-smooth tonearm movement can be traced back to the cueing mechanism, as this is what helps to control the action of the tonearm’s lifting and lowering motion. Therefore, a run through of the fix suggested above in Issue 3 with regards to damping oil should be considered.

Next up, let’s look at some of the most common audible issues you may encounter, and which can be traced back to the tonearm.

Some of these issues will be caused by other factors, or even a combination of issues, but as any part of an elimination process to root out the cause the tonearm can always be checked out.

Issue 6: Hum or Noise When Playing Records

Hum is an issue that can be caused by a number of different things, but sometimes it does trace back to the tonearm.

If you’re getting hum when playing your records and have checked out a few other probable causes but without success, it’s always worth looking at the tonearm ground wire (if your turntable tonearm has one). Read the user manual to ensure you know how to properly check the ground wire is well connected to the ground terminal.

Hum or other noise interference can also often be traced back to the cartridge, so verify first that the cartridge is properly attached and connected to the tonearm. It’s always advisable to look up specific cartridge advice before delving into playing around with such a delicate component.

Issue 7: Weak or No Sound During Record Playback

If the tonearm is the culprit for weak or no sound at all when you’re playing your records, it will most likely be one of two issues.

The first is likely to be the classic tonearm balance fix. Without the correct Vertical Tracking Force (VTF), the appropriate weight will not be being applied to the stylus and it won’t track the record grooves properly. If the VTF is too light, bass frequencies will be lost and the overall sound will be weak and, in extreme cases, almost nonexistent.

The correct VTF is determined by the manufacturer of the cartridge, and they’ll state a weight that is usually between 2-3 grams, so check their guidelines for optimum set-up.

The other possible cause for weak sound output that can be linked to the tonearm is the bridge. Using the guidelines from Issues 2 and 3 above, check the height of the bridge to ensure it isn’t preventing the tonearm from lowering far enough to bring the stylus into proper contact with the record.

Issue 8: Only Hearing Sound in One Channel When Playing Records

The tonearm shouldn’t be the first port of call for this issue, but if you’ve checked out the other logical areas that could cause you to be hearing only the left or right channel, then tonearm balance and VTF are two things you can quickly and easily verify.

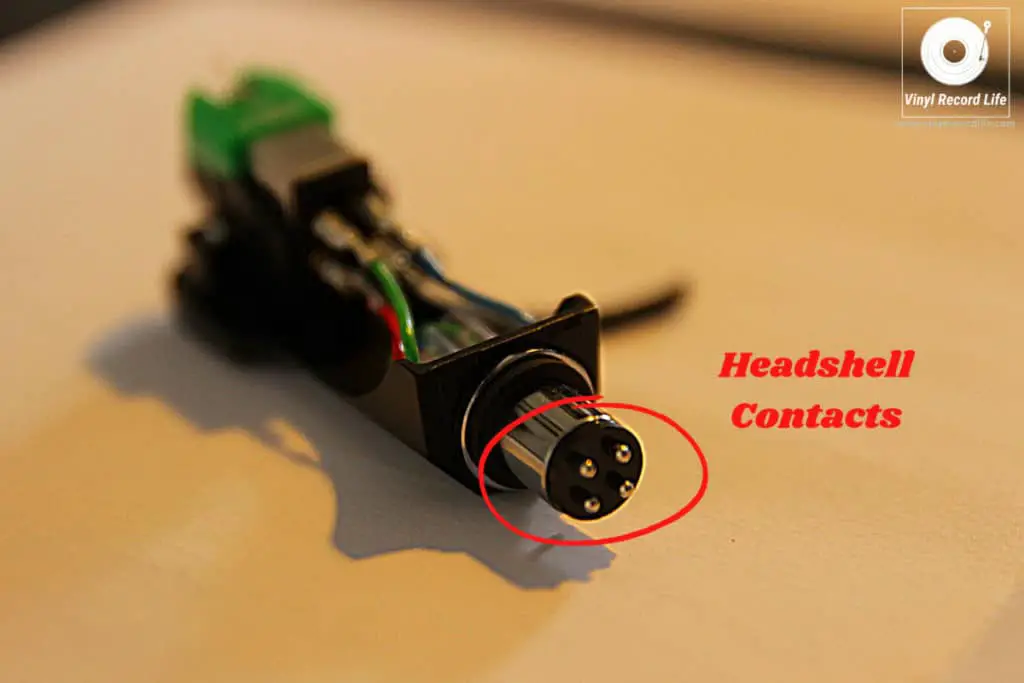

If that doesn’t help, then try disconnecting the headshell from the tonearm and clean the contacts that connect these two components. A dab of rubbing alcohol on a cotton swab should do the trick. You can also check the connections between the cartridge and the headshell to ensure they are clean.

Issue 9: A Skipping Record

A very common problem and one which we’ve all faced, or will face, at some point! A skipping record can be caused by a few different factors, but the tonearm is a good place to run some checks.

As per Issue 7, the VTF can often be a key factor in a skipping record. If the stylus pressure is too light, you won’t only experience weaker sound, but the stylus can also jump out of the record grooves, resulting in a skipping record. This is detrimental not only to the listening experience, but also to the record as the stylus can damage the groove when it lands again.

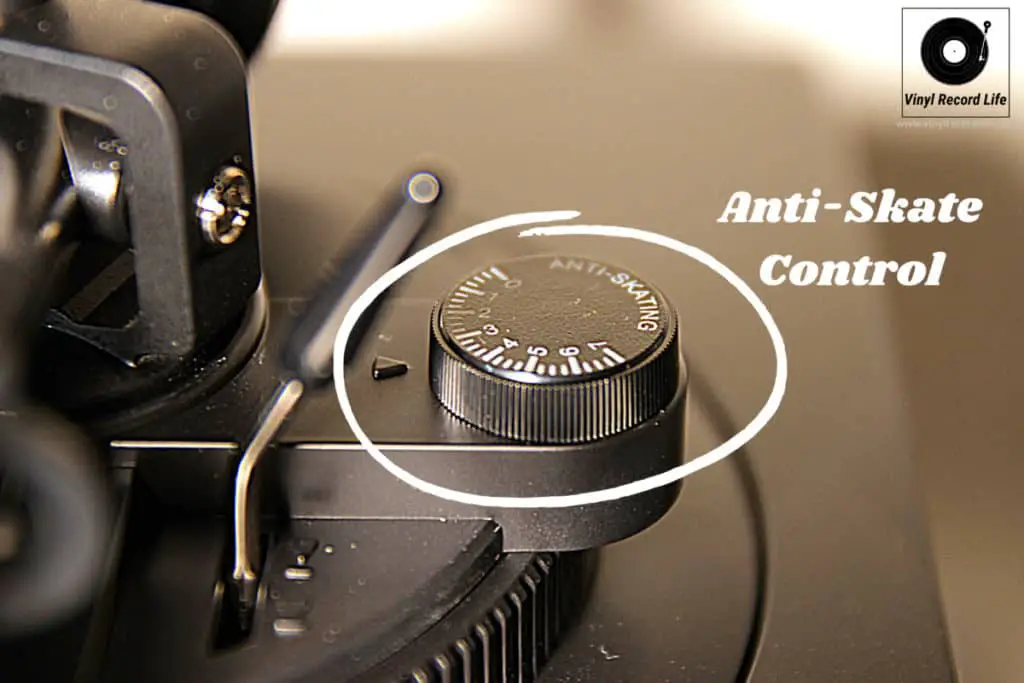

The anti-skate on the tonearm is also something that you should check if experiencing a skipping record. The purpose of anti-skate is to counteract the natural movement inwards of the tonearm, by applying a small force outwards to maintain a balance. If the anti-skate is off, record skipping can be a result.

A skipping record can also sometimes just be down to a dirty record, and an excess of debris in the grooves causing the stylus to jump out. I use this cleaning kit, which also includes a stylus cleaning brush and fluid, as it’s great value, does a good job and includes a few different pieces of kit.

Issue 10: Interference When Moving the Tonearm

If you hear any untoward sounds when moving or touching the arm but which don’t happen during playback, such as rustling or crackle, the most common cause is the tonearm’s cabling.

The wires inside the arm sometimes rub the walls of the tube, which in turn creates static, or they rub against one another which can also lead to induced current. This is more likely to occur in dry environments, so if you live in a warm, dry climate this could well be an explanation.

Getting into tonearm wiring is not as straightforward as some of the other fixes outline above, so unless you’re confident this may be one that is best left to a professional or at least someone with more experience.